Laser Cutting Design

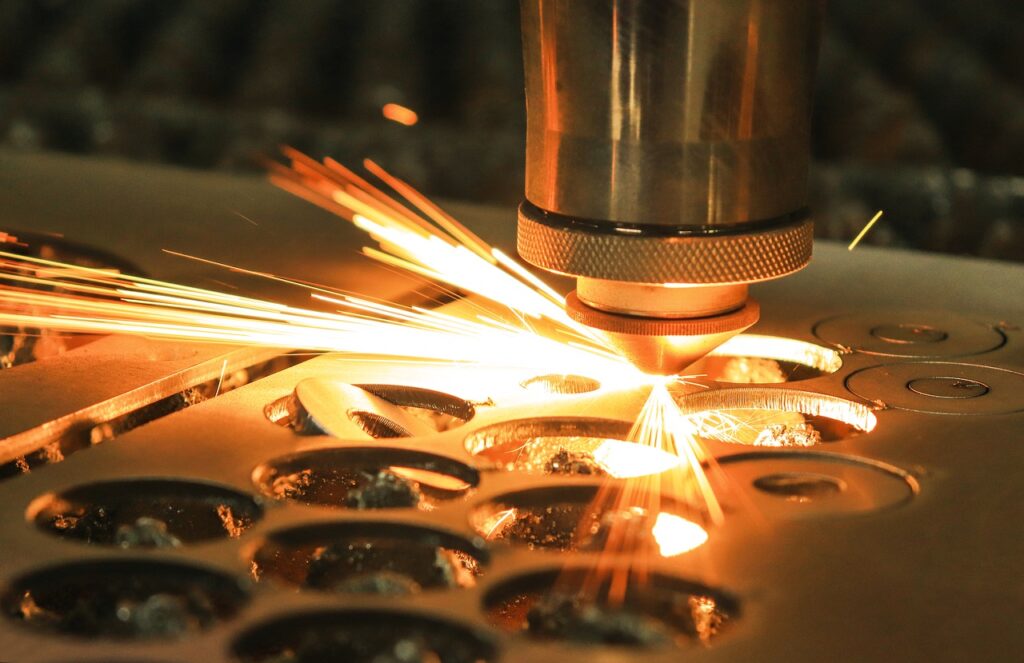

Laser cutting is the most used method when it comes to the cutting of metals due to its cost-effectiveness and high precision. Compared to the other methods of cutting like the conventional cutting techniques, this laser cutting achieved accurate cutting even with the smallest details, regardless of the designs. For example, if there are some complex designs like very sharp angles, smooth curves and lace patterns laser cutting will help you obtain the best results that match the utmost standards.

However, though this laser cutting technique being useful, you may need one to have the proper training in order to get the best from it. For sure, these laser cutters help in the provision of incredible precision, however in the case, they are not used in the right manner, then you can have everything being ruined. Your entire project could turn out into nightmares.

There are many companies that have adopted this laser cutting technology. USA Contract Manufacturing Specialists is among these companies that have embraced this technology. However, though this laser cutting offers a number of advantages such as reliability, cost-effectiveness, and good cutting precision, there are still other things that you will need considering. These aspects are that ideal whether you are using our services or have your own laser cutters.

Thus, before you embark on any laser cutting processes, it is important to make sure that you are conversant with what is needed. First of all, you cannot laser cut on any material types, as they could emit toxic fumes that pollute the environment. Metals are usually the main materials used in this laser cutting process.

More so, you will need to have the right gears when operating the laser cutters. Therefore, you need to get everything straight before you start working making sure that all you need is available and well prepared. You need to have things like the computer drawing program to aid in the coming up of the designs, the metal you need cutting, and the protective equipment.

How to design for laser cutting

Be it you are an entrepreneur or engineer, just the frequent user of laser cutting and prototypes will always allow the manufacturing and designing of products with precision and speed at the most minimal costs.

However, although the laser cutting requires to cut pieces on flat materials like the sheets of metal, this does not necessarily mean it cannot create the objects with their designs. They’re also a range of tools and equipment’s designed together with these laser cutters that make it possible to manufacture products and parts. This is however possible with the use of assembly and creative thinking and some design work.

Therefore, to make sure you are meeting the quality and precision of the products that are you cutting using the laser cutting machines, then you need adhering to some specific guidelines. That is what we are going to base to help you get the best deals ever.

Scale the design to the finished size

Before sending your work to the lesser cutting machines, it is important that you ensure you are designing it to the scale. if the metal piece that you need is to be 12-in Squared, then make sure the design is exactly to make sure the proportions or scale are right.

Don’t add multiples

When you plan of having two more pieces cut from the same metal material, all you need doing is sending each of the pieces and letting the laser cutting company knowing the number of multiples that are needed. These laser cutters will plan out how these shapes will be arranged on the cuts while utilizing the material to the minimum. By crowding your design with different copies of the same images, this could complicate the cutting processes potentially increasing the costs.

Only submit the design to the cutter

Before sublimating your designs t the laser cutting machine, you need to make sure that the borders, gridlines, comments, and any notes are removed. These markings need not being a part of the final product. Therefore it is ideal having them removed beforehand.

Design using software that creates vector files

All the laser cutters need to have the vector files like those created in the inks cape and the Adobe Illustrator. Some of these common files include the .eps, .dxf, .ai among others. It’s important that you ask the laser cutting company the formats they provide. Mostly, most of them will support files from the software you will use in the designing of your creation.

Determine which material is best for your design

Selecting the right materials for design is always essential. It is important that you discuss your project goals with your laser cutter company so as to determine the strongest performance materials for the applications. Most of the laser cutting is done using metals like copper, steel, brass, aluminum, and stainless steel.

Convert your text into shapes or “outlines”

Another major mistake is keeping the texts in the designs active instead of converting them into shapes. The laser cutters are not able to process the active text boxes. Therefore, when you move your cursor over the text in your design and it shows the editing bar, this means it is in the active text box. For the laser cutters to process properly, you will need to turn this text box into shapes.

Connect your design

One of the most common mistakes that most new design creators make is the failure to bridge their text and design in their files. Usually when this is done, then the shapes of the products will be lost when they are not connected primarily to the materials in the design. The addition of these bridges is what enables the laser to cut cleanly while also keeping the entire designs together without having to lose the pieces.

Reduce the complexity of your design where possible

For each laser cut and punch needed, the manufacturing costs will always be on the rise. More so the most complex designs have also the delicate details and smaller pieces that could make the design more susceptible to breaking and less robust.

Therefore, when in doubt, make sure you are creating the simpler designs as possible to reduce in the costs and also to help in the creation of more stable objects. With laser cutting, you can be able to create impressive prototypes, equipment’s, and impressive art with much ease.

Eliminate open shapes

By having the unfinished and open shapes, this will not work well with the laser cutter. Therefore, you need to make sure that all your designs are self-contained and complete. Failure to do this will make the cut not to function and even make the end product look different from what you expected.

Remove all intersecting lines

Your design work could have overlapping artwork and also complex. Therefore, you will need to have these overlapping lines eliminated. When this is the case, you will find out that the laser cutter will cut on any lines in your design leading to unintended cuts thus ruining the entire metal.

Make sure any cut-outs or designs are large enough

It is important also to ensure that your designs or any cut-outs are large r than 1X thickness of the material that you using. Any cutouts that are smaller than this size will not be that accurate also the laser cutters could not be able to have them cut. The small and thin features are usually that delicate to break than the larger designs. This one aspect you need considering during you’re designing the piece of work.

When designing your materials for laser cutting, to make sure you are getting the best desired results, then you will need to take into consideration all aspects. Make use of the manual in case of uncertainties whether on material compatibility, settings or numbers, and pay attention to all details as all these matters.

If you need any of our services, feel free to get to us and we will give you a free quotation. The company guarantees you that you will get the value for your money in any service that you hire from us. We have the right technicians and machines to help you out on any metal project that you could be having at your individual or business needs.