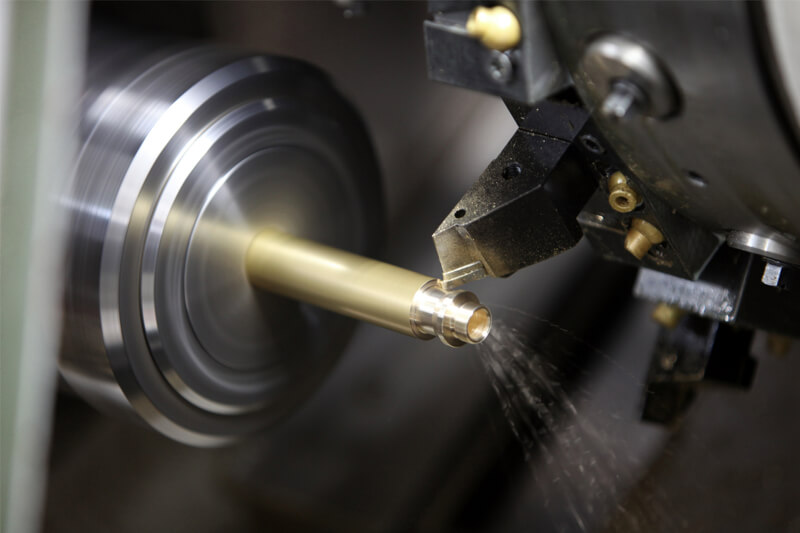

CNC Turning

CNC turning can be defined as a process where single-point tools for cutting are matched with plastic material, stone, metal, and wood. These materials then spin and the tool will pass through the two axes movement do as to allow the generation of the precise downwards dimensions, lengths, and sizes. This practice can either be accomplished either on the inside or the exterior of the material via the boring process.

More so, this could be used in the generation of the tubular mechanisms in the differentiation of the necessary measurements. this activity can be done manually, however, with the more advanced computer-controlled machines that are automatic, this task needs not the continuous regulations by the operators.

CNC turning machines also referred to as the CNC lathe machines are mainly needed in the industrial mechanical industries that perform the various forms of operations like sanding, drilling, and cutting. The best thing with the use of these machines is that they can help in the reduction of the turnaround time which generally boots one productivity and hence profitability over long periods of time.

The main reason being that there are various turning centers that work on different materials such as plastics, metals, and wood. These turning centers have however gained more popularity and been adopted by both the large manufacturers and the small shops.

Here are some things that you need to consider when you need buying the CNC turning machines:

CNC turning machines are ideal for the machining of important components

These CNC turning centers are mainly used in the performance of intricate turning operations in the production of components such as table legs, stair railings, and auto parts among others. The cutting and turning operations on the materials will happen repeatedly to ensure the large scale end-product manufacturing.

Perform parts production that require the circular motion

There are always some materials that cannot be performed under vertical or horizontal milling operations. Therefore, make sure that the materials you are going to use are able to withstand the stress of the turning processes since these cutting operations are done in a circular motion.

An operator is needed in the operation of the CNC turning machine

It is crucial for hiring and training, someone, to operate these turning centre. Basically, the operator you choose should be able to be proficient in G-code programming skills that are essential when it comes to controlling the CNC turning centre.

Most of the advanced CNC turning machines are able to perform multitasking productively

It is likely that you are able to obtain advanced turning centres in the performance of turning operations that have drilling or milling operations. This one set up can really help in saving a lot of time and also the accuracy levels are high as you will not lose any information due to fixturing.

Turning centres have two types of turret

Typically, the CNC turning machines that have servo turrets perform much faster the turning operations compared to those that have the hydraulic turrets. That is why you will find out that the servo turret turning centres are that costly than the other models.

Newer models have ergonomic coolant tanks

This is a unique feature that helps in the improvement of chip management. The coolant tank can be pulled out with much ease for maintenances and cleaning.

It requires occasional maintenance

The old turning centres need frequent maintenances since the cutting tools will need replacement with the new ones so as to be able to perform precise turning operations. With the use of the new CNC turning machines that have state-of-the-art spindle system technologies, then you can be sure of saving the maintenance costs. Meaning that these machines have cartridge designs that help in the protection of internal bearing spindle systems and elimination of hefty maintenances.

Advantages of CNC Turning

Among the many manufacturing methods, CNC turning is the eldest. This technique has been in use for hundreds of years by the different cultures in the delivery of precision components. Since then, there have been so many technological advancements and now these machines are used in the creation of components to their highest accuracy and quality.

Services such as CNC turning and grinding are among the most used in the various modern industries such as the motorsports industry where the need for fast turnaround of products and high-quality parts is needed. Here are some of the advantages that are associated with this manufacturing method for the modernized companies that need precision parts;

First, CNC turning offers very cost-effective prototype parts.

That means that companies in search of developing new products can explore their ideas and designs without heavy financial investments. This is usually ideal mostly in the industries that have great innovation deals taking place. Such industries include the aerospace industries, the motorsports industries, and the other industries with competition as a key element. Prototyping is a very ideal part of processing and the modern CNC technologies and machinery allow these items being produces in a very efficient manner and cost-effectiveness.

Production of high-quality precision parts

Another key benefit of CNC turning is that it provides precision parts that are very crucial in intricate designs that are usually manufactured for the highest safety and efficiency such as the aerospace and motorsports sectors. However, this is all possible due to the technological advancements in CNC turning centres.

This high-quality precision components that are able to be produced is a clear identity that companies only rely on the best quality parts as components of their design. Meaning they get more successful in their endeavors whether business or sporting. Thus, when quality is the utmost important aspect CNC turning is a highly reliable technology to adopt.

The most complex parts are able to be manufactured

With the use of the CNC turning, milling, and grinding, you can be sure of manufacturing the high precision and complex parts. As a matter of fact, the complexity of the items that are produced will depend on the machinery used by the manufacturing company. Therefore, for the best results ever, it is essential to find contract manufacturers with the ability and capacity of producing the best parts. Also, you need to find a company that heavily invests in the best CNC machinery to carry out their tasks.

Therefore, doing thorough investigations on the kind of processes and equipment that the manufacturing company uses is relevant. This will give you the surety that they are producing the high precision surfaced and complex components that you are in need of. The best companies do advertise these capabilities; one thing you should look for.

Mass production of components

Another great advantage of using these manufacturing companies that have adopted the latest technologies is that they can be able to produce bigger batches of components. Again, this is dependent on the technologies used and the size of the workshops that the manufacturers have. Nevertheless, bigger batch work and efficiency are that possible, thanks to CNC turning and grinding technologies that have led to better results for contracting companies. Some of the advantages that accompany the bigger batch production are more cost-effective parts and faster turnaround times.

USA Contract Manufacturing Specialists” is a world-class engineering group that has a speciality in the manufacturing of small to medium-sized complex, high tolerance, super finished and precision machined parts for leading supply chain and OEMs companies like Industrial markets, Motorsport, Aerospace and Defence. The company operates all state-of-art CAD/CAM designs and complex axis, EDM production equipment, grinding, milling, turning and simultaneous machining with high capital investments to keep the facilities on track with latest technologies and customer needs.

This combination of proven capabilities, production facilities, and expertise is what makes the company a reliable supply of high-quality components fulfilling the longer-term strategic supplier contract necessities. Work with this company for great ideas and contracts.

If you need any of our services, feel free to get to us and we will give you a free quotation. The company guarantees you that you will get the value for your money in any service that you hire from us. We have the right technicians and machines to help you out on any metal project that you could be having at your individual or business needs.